WFS Steam Filter Station

A pre-piped solution to provide filtered steam for sterilization, pharmaceutical, and food & beverage applications. The steam separator and 5 micron filter element improve steam quality to 97% or greater at the outlet of the filter. Piping prior to the filter to be SA-53B Sch 40 with cast iron fittings. Piping downstream of the SS filter to be SA-312 Sch 40 with stainless steel fittings. Options & configurations available.

The WFS Steam Filter Station is the ideal equipment to help medical facilities meet the new ANSI/AAMI water quality regulations for safe surgical instrument steam sterilization.

Steam Filter Stations Include:

- Steam separator

- 304 SS Filter Housing with 4 micron element

- (2) UTS600 Steam Trap Test Stations with UFT450 Float & Thermostatic Steam Trap Modules

- Thermostatic Air Vent

- Pressure Gauges with pigtail loops – Ball valves for isolation

- Interconnecting piping or components only

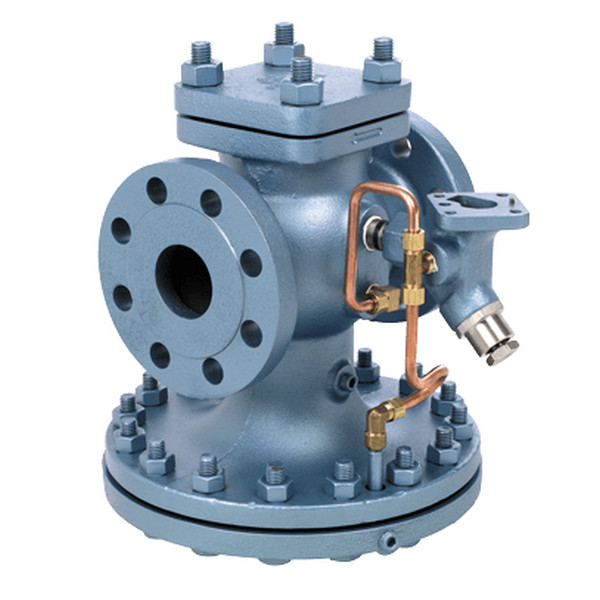

Watson McDaniel Pilot Operated Regulators

One main valve plus pilot or combination of pilots will perform pressure regulation, temperature regulation, solenoid regulation, back pressure regulation, pressure and temperature regulation, pressure, temperature, solenoid regulation, pressure/solenoid regulator, temperature/solenoid regulator, pneumotor temperature controller, air pilot, electronic timing control. Main valves available 1/2” thru 2” threaded 250 psig @ 450°F. 2” thru 6” 125 lb flanged 250 lb flanged.

Pilots

- Pressure

- Temperature

- Solenoid

- Air

- Back pressure

- Pneumatic temperature controller

- Electronic timing

- Any 3 combinations above per main valve

Main Valves

- 1/2”-2” screwed

- 2”-6” 125-lb flanged

- 2”-6” 250-lb flanged

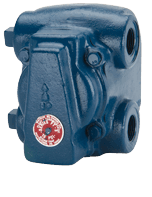

Steam Traps

Float & Thermostatic Steam Trap – Designed to freely remove large quantities of condensate. For use on: Unit & space heaters, water heaters, converters, pressing machines, steam process equipment, draining mains & risers – low pressure, heat exchangers, coils. Features noiseless operation, in-line servicing, two side inlets & outlets – easy installation, valve, seat, float & air vent – stainless steel.

Inverted Bucket Steam Traps

Recommended for all services where the most important requirements are overall operating efficiency, freedom from maintenance, and long, trouble-free service life. Designed for pressing machines, fire molds, cookers, unit heaters, high-pressure drips, dryers, laundry equipment. Features only 2 moving parts, heat-treated stainless steel valve & seats, free-floating & frictionless valve lever assembly. All working parts are attached to cover for in-line service.

Turbo Disc Trap

Designed to remove condensate & air automatically from steam lines. Freeze-proof design can be easily achieved. Typical uses are: Sterilizers, pressing machines, tanks, tracer steam heating lines, industrial processing equipment, small dryers, high-pressure drips. Features: Stainless steel, excellent capability for handling light to medium loads, works efficiently in any position, snap-opening provides purging action in unit being drained, compact for easy installation. The disc trap uses the higher kinetic energy of flash steam over water to close the trap with static pressure.

17C Low Pressure Traps

Low pressure traps. Standard, swivel, and vertical patterns. Max pressure: 25 psi. 1/2 inch by 1/2 inch.

| Orientation | DPN | Size |

|---|---|---|

| Standard | 7632 | 1/2″ |

| Standard | 262591 | 3/4″ |

| Swivel | 7634 | 1/2″ |

| Vertical | 7633 | 1/2″ |

8C Steam Traps

Angle steam trap is available in 1/2″ and 3/4″ pipe connections.

Straightaway Steam Trap has a 3/4″ pipe connection. For radiator or convector locations that don’t allow for use of an angle trap.

High quality brass body, cap nut & tailpiece. Renewable seat & thermostat. Thermostat, pin & seat are of a non-corrosive alloy for long life under actual service conditions. Stainless steel pin & seat available. Max 25 psi.

| Orientation | DPN | Size |

|---|---|---|

| Angle | 7638 | 1/2″ |

| Angle | 7635 | 3/4″ |

| Straightaway | 7636 | 3/4″ |

Angle Steam Traps

DPN 7637 – No. 9C Angle Steam Trap. 1” pipe connections. Body, cap nut & tailpiece are high quality brass. Seat and thermostat are renewable. Thermostat, pin & seat are of a non-corrosive alloy for long life under actual service conditions. Stainless steel pin & seat available. Max 25 psi.

DPN 7638 – NO. 8 Trap. 1/2” x 1/2” angle pattern. All bronze body, brass cap & unions. Thermostat is non-corrosive alloy for long life under actual service conditions. Thermostat & seat are renewable. Seat & pin are stainless steel. Max 50 lbs.

DPN 7337 – NO. 9 Trap. 3/4” x 3/4” or 1” x 1” angle pattern only. All bronze body, brass cap & unions. Thermostat is non-corrosive alloy for long life under actual service conditions. Thermostat & seat are renewable. Seat & pin are stainless steel. Max 50 lbs.

Watson McDaniel W910 Series Compact Control Valve

Pneumatic/Diaphragm Actuated – Watson McDaniel Pneumatic Actuators are direct acting and use an air signal from an external control device to create a modulating control action. The force of the air signal is received into the actuator through a top port and distributed across the full area of the actuator’s diaphragm. The diaphragm presses down on the diaphragm plate and spring return assembly, which then moves the valve stem and plug assembly downward to stroke the valve. This actuator will move to a stem-out position in the event of air signal failure. The choice of valve action (stem-In-To-Close or stem-In-To-Open) will determine its signal failure position. Available through 1/2” through 4”, with either union or flanged connections, as a 2-way or 3-way valve.

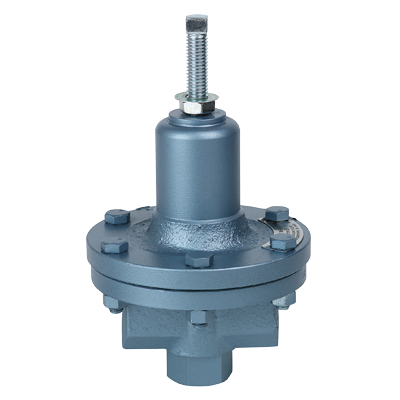

Watson McDaniel Style O Pressure Reducing Valve

Good for steam! The “O” Series Self-Contained Pressure Regulating Valves are used for reducing pressure in steam, air, and water systems. Commonly used in heating and other process applications. For sizes 1-1/4” through 2”.

Suction Tees

Suction Tees – Cast iron, bronze, or stainless steel construction.

This specialized pipe fitting is used for Blending, Agitation, Recirculation, Mixing, Aeration, Heating. Sizes 1/2” to 3”. Under pressure, the operation medium enters the tee through a convergent nozzle into the suction chamber. This increases the velocity of the operating medium as it leaves the nozzle & lowers the pressure in the suction chamber, causing the medium in the suction system to flow through the suction tee.